Researchers develop renewable methane from waste wood

01/23/2019 / By Edsel Cook

A new German-developed biogas plant has recently succeeded in creating synthetic natural gas (SNG) from biomass. The KIT news page reported that the methane produced by this pilot facility is just as good as its fossil fuel-based equivalent.

The plant can turn a mixture of gases into usable biofuel. The raw materials are extracted from everyday waste products of biological origin.

The resulting biogas can be used in both cogeneration (combined heat and power) and pure heating plants. It can also serve as fuel for ground vehicles that run on methane.

Developed by the Karlsruhe Institute of Technology (KIT) and the Research Centre of the German Technical and Scientific Association for Gas and Water (DVGW), the plant is designed to be compact and easily transported. It was fabricated in Germany, transferred to Sweden for testing, and returned to KIT for further refinement.

The plant represents one of the latest efforts to replace fossil fuels with their renewable counterparts in the heat generation and transportation sectors. Researchers say biogas and synthetic natural gas can match petroleum-based products when it comes to storing and releasing large amounts of chemical energy. (Related: Irish researchers detail a potential solution for tackling plastic waste.)

New catalysts make it more efficient to turn biowaste into biofuel

A biogas plant ferments biowaste to produce synthetic natural gas. This SNG is rich in hydrogen molecules, one of the best carriers for chemical energy, as well as carbon dioxide and carbon monoxide. It undergoes further conversion through methanation to create usable fuel.

Biogas plants are tailor-made for countries with plenty of lumber products. For this reason, the German researchers partnered with Sweden, which is looking for ways to get much better use out of the waste wood produced by its forestry sector.

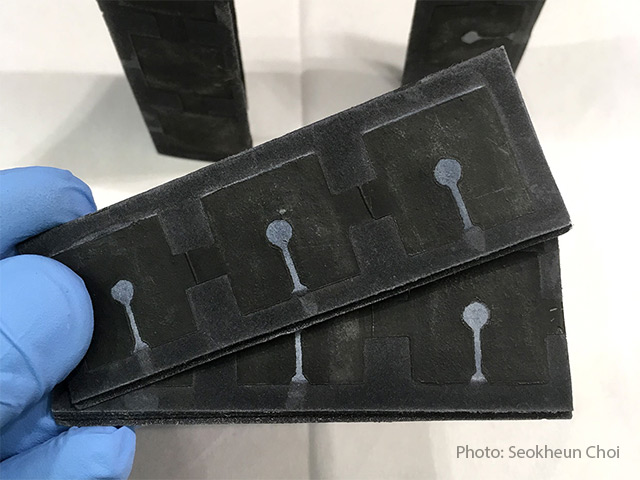

The Swedish city of Köping hosted the KIT-DVGW plant for several weeks. While there, the plant tested brand new honeycomb catalysts that increased the efficiency of the methanation process.

“In a single-stage process, metallic nickel catalysts convert hydrogen and carbon monoxide and, in case of sufficient hydrogen supply, also carbon dioxide into methane and water,” said KIT researcher Siegfried Bajohr. He reported that the new methanation plant proved its efficiency during the entire trial period.

The synthetic methane produced by the plant was used to power natural gas vehicles operated by their Swedish partners. Bajohr added that the cars and trucks ran on biofuel with the same efficiency as they did on natural gas from fossil fuel sources.

For even cleaner results, use clean energy sources

In addition to powering ground vehicles, the methane produced by biogas plants could be easily integrated into the natural gas infrastructure found throughout Europe. Bajohr’s colleague in KIT, Felix Ortloff, believes that this puts biowaste-based methane in a very good place to replace natural gas.

The methanation technologies introduced by the new plant can also be hooked up to renewable energy infrastructure and used for power-to-gas production. Hydroelectric, solar, or wind power can be used to split water into hydrogen and oxygen.

Honeycomb catalysts will then be added to trigger a reaction between hydrogen and carbon dioxide. This method is just as clean as the biowaste-conversion equivalent since it uses ordinary water as the source of hydrogen.

Bajohr and Ortloff say that such power-to-gas production systems will be able to greatly reduce the strain on power grids. Because the plants can make complete use out of all carbon dioxide produced during the methanation process, their output could be boosted to double their normal capacity.

Inventions.news will keep you apprised of the latest developments in renewable energy.

Sources include:

Tagged Under: biofuel catalysts, biofuels, biogas, biogas production, biomethane, breakthrough, Clean Energy, environment, future tech, green energy, inventions, Methane, natural gas, power, renewable energy